Coatings for industrial areas

Industrial application areas

Where should your coating be used?

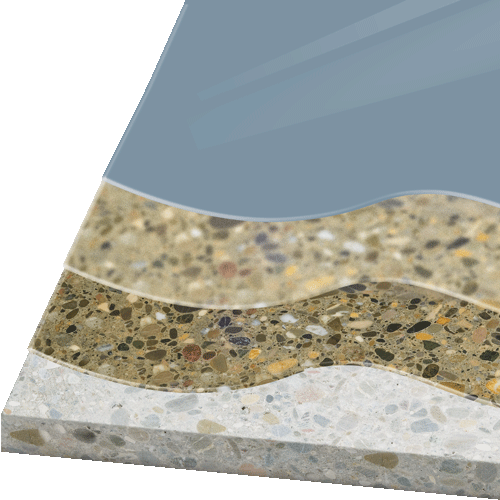

Your production methods are as individual as your products. Modern assembly lines and operating processes that are coordinated down to the last detail need a solid foundation to make a strong impression, and not just on your customers. Coatings in production and manufacturing facilities – as mechanically highly resilient, durable floor coverings with robust properties – offer you just that. The individual requirements of the various industry sectors are more than met by KLB systems. Among other things, they are characterised by their ease of cleaning, slip resistance and transportability. For large-scale industrial, production or assembly halls, we at KLB have the perfectly matched system solutions when it comes to efficiency, flexibility and a strong performance.

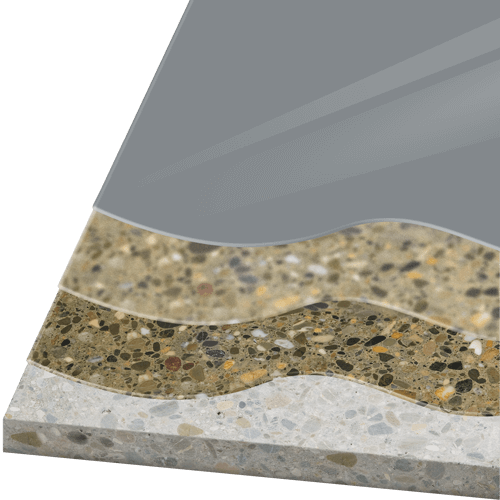

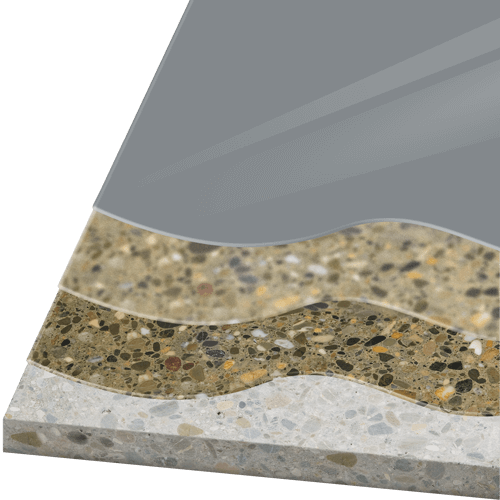

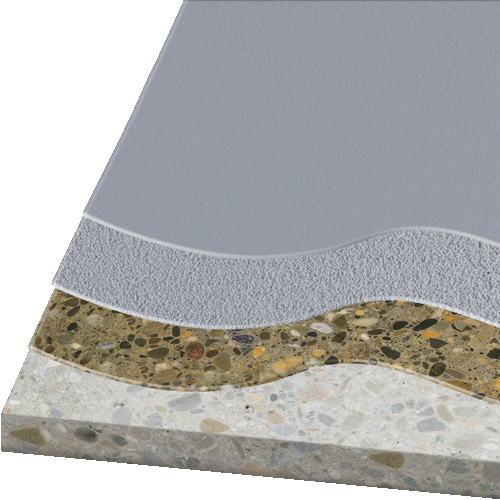

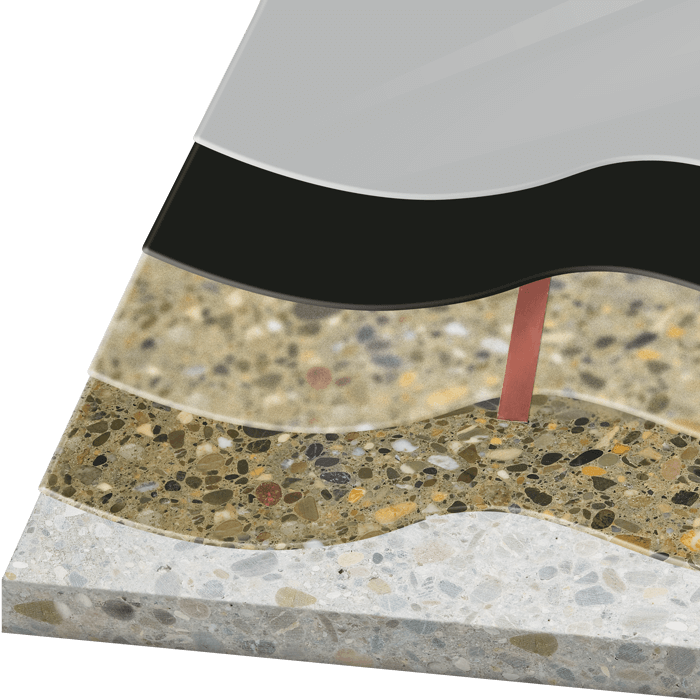

KLB INDUSTRIAL EP Standard

Smooth, slightly slip-resistant epoxy resin coating for commercial and industrial applications

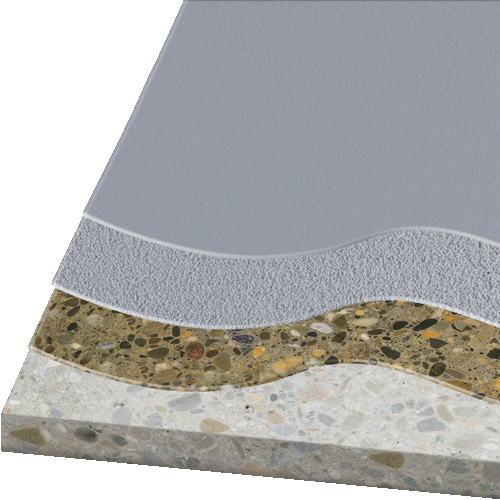

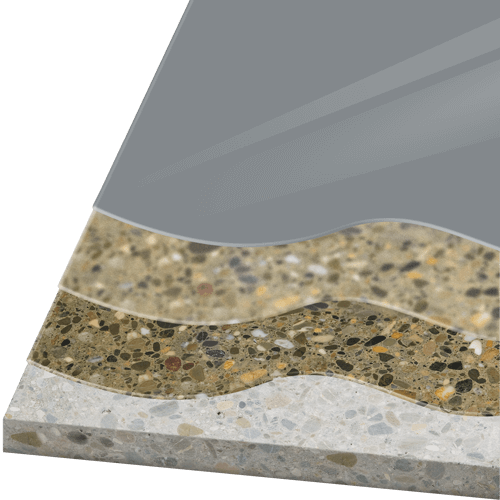

KLB INDUSTRIAL EP Rapid

Rapid-setting and quickly reusable epoxy resin coating in smooth or slightly non-slip

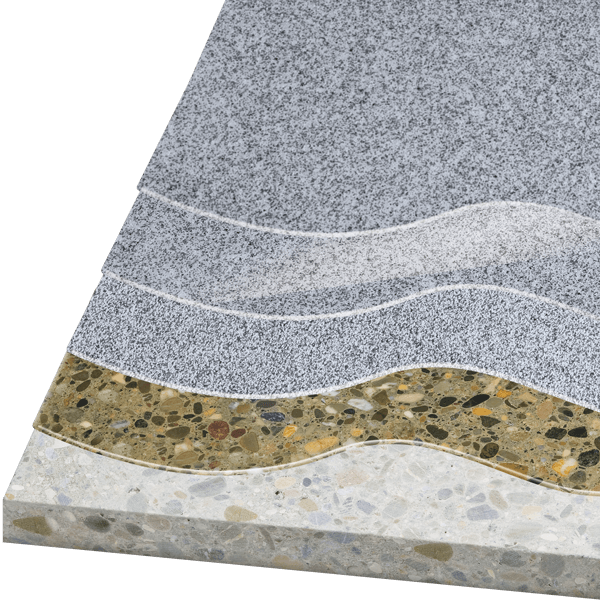

KLB INDUSTRIAL EP RX

Scattered and non-slip epoxy resin coating

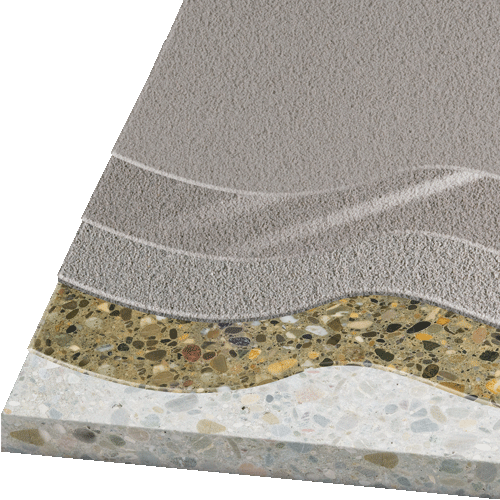

KLB INDUSTRIAL EP RX Robust

Slip-resistant, durable epoxy resin coating to be scattered with coloured sand

Floor spaces in warehousing and logistics facilities are constantly exposed to high levels of stress by industrial trucks and the movement of pallets. Robustness and high resistance to wear and tear are important properties. The KLB floor systems in this category are particularly suitable for dealing with mechanical loads.

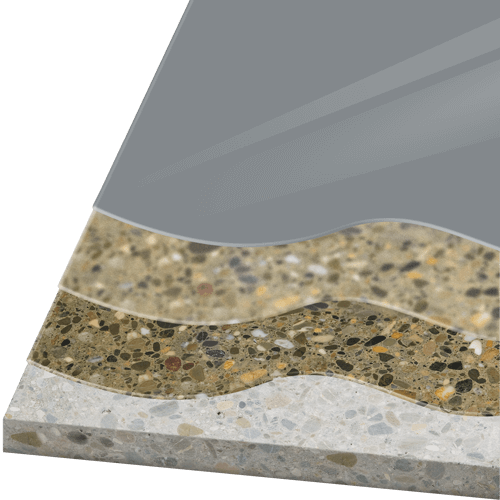

KLB INDUSTRIAL EP Standard

Smooth, slightly slip-resistant epoxy resin coating for commercial and industrial applications

KLB INDUSTRIAL EP Rapid

Rapid-setting and quickly reusable epoxy resin coating in smooth or slightly non-slip

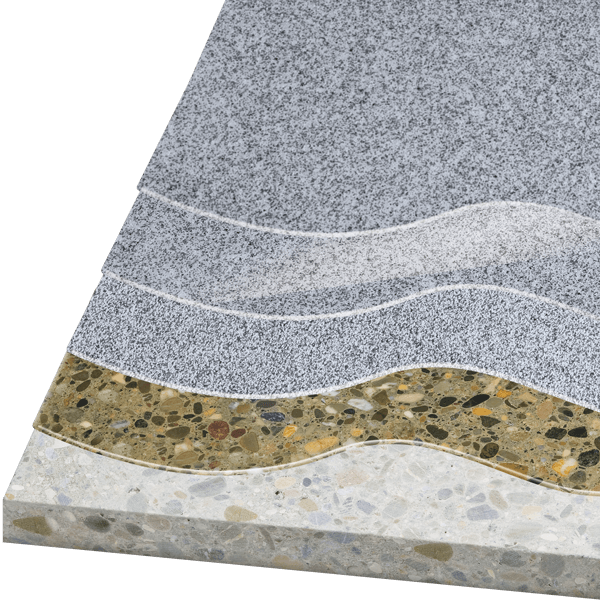

KLB INDUSTRIAL EP RX

Scattered and non-slip epoxy resin coating

KLB INDUSTRIAL EP RX Robust

Slip-resistant, durable epoxy resin coating to be scattered with coloured sand

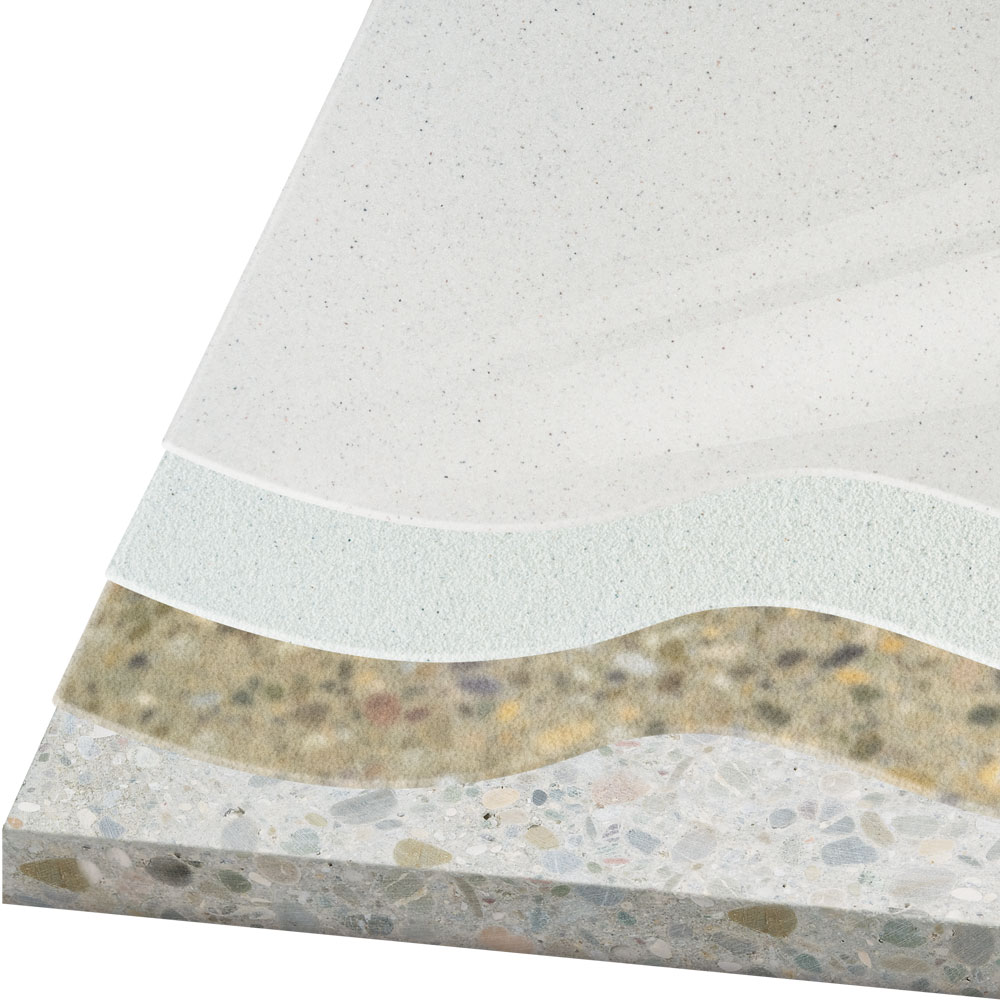

From hygienic reactive resin floors – jointless, smooth, easy to clean and disinfect, also set to be electrically conductive where necessary – through low-VOC floors for clean rooms over to coatings with good chemical resistance: KLB offers a suitable system for every laboratory.

KLB INDUSTRIAL EP Standard

Smooth, slightly slip-resistant epoxy resin coating for commercial and industrial applications

KLB INDUSTRIAL EP Rapid

Rapid-setting and quickly reusable epoxy resin coating in smooth or slightly non-slip

KLB INDUSTRIAL EP Screed

Smooth epoxy resin mortar coating

KLB PROTECT WHG EP

Chemical-resistant epoxy resin coating for water protection (WHG) with approval according to DIBt (building authority approval)

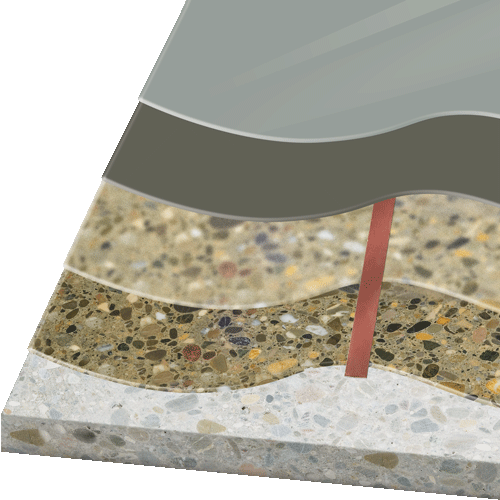

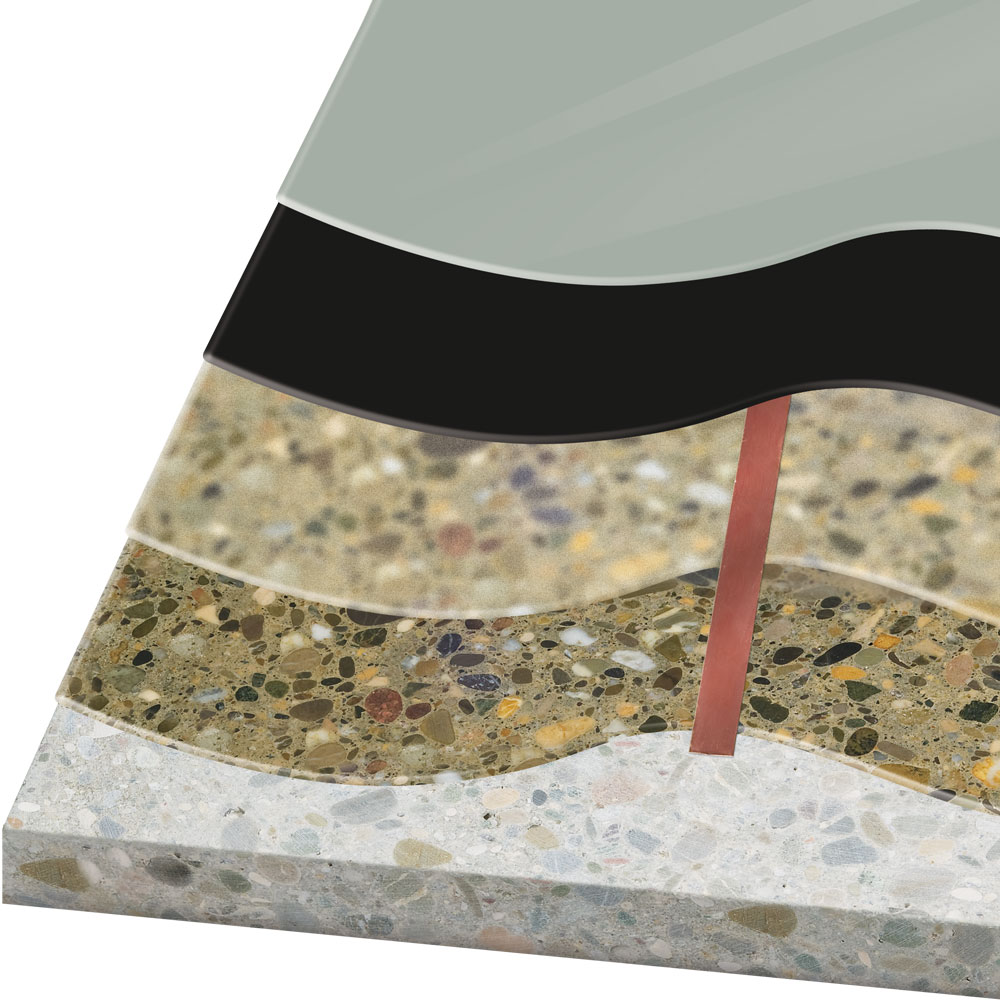

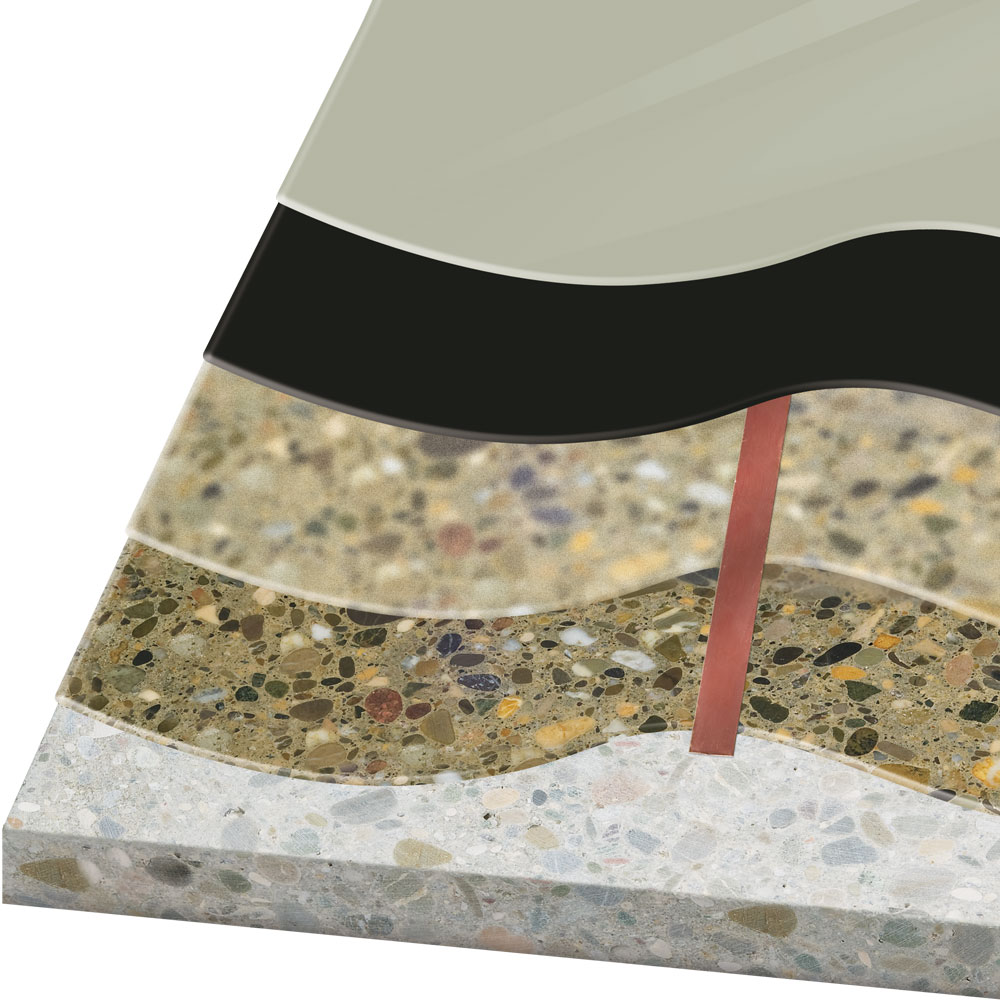

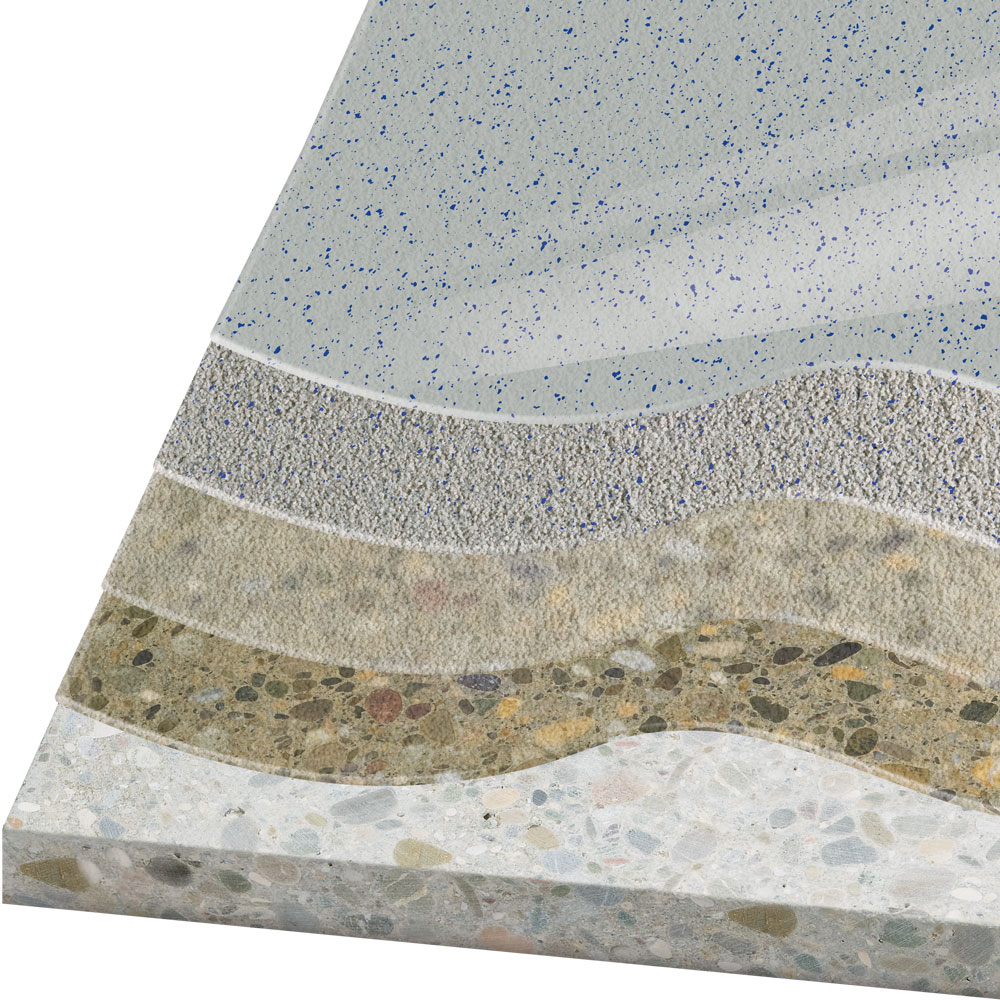

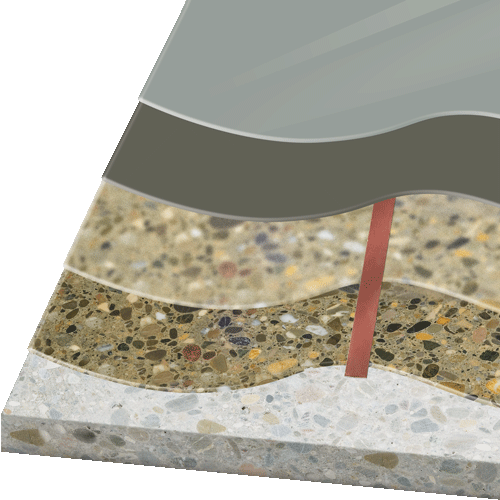

Technical innovations are the igniting force behind every development. However, to prevent the spark from being ignited at the wrong moment, we offer you KLB systems that meet both safety requirements and your high production standards – be it conductivity in accordance with ESD specifications (electrostatic discharge) or explosion (EX) protection. Our coating systems are suitable, for example, for operating theatres with sensitive electronics or measuring equipment, server rooms, clean rooms in the semiconductor industry, production areas of electronic components in electrical engineering or in the chip industry. Just like us, our coatings are reliably grounded partners in chemical-technical production and storage facilities where explosion protection guidelines must be observed.

KLB PROTECT WHG CONDUCTIVE EP

Chemical-resistant epoxy resin coating for water protection (WHG) with DIBt approval (building authority approval), electrically conductive

KLB CONDUCTIVE EP EX Standard

Smooth, electrical conductive epoxy resin coating with EX protection

KLB CONDUCTIVE EP ESD Standard

Smooth, light-coloured and homogeneously conductive epoxy resin coating for increased requirements in ESD areas

KLB CONDUCTIVE LOW-VOC EP ESD Exclusive

Smooth, low-emission, homogeneously conductive epoxy resin coating for requirements in ESD areas

"Time is Money": to live up to this slogan, we offer you a wide range of KLB systems with very fast curing that can be quickly subjected to mechanical or chemical loads again. Surfaces can be put back into service within short time (only a few hours, depending on the system) and costs are significantly reduced due to the minimal downtime. Rapid reusability is the main requirement for our specially developed "Rapid" range of epoxy, polyurethane and acrylic resins. They stand our for their appearance and robustness, while offering calculable time windows for installation and thus minimal operational interruptions. Especially for renovation and maintenance, manufacuturing processes are only briefly interrupted and ongoing operations are not disturbed. Due to the particularly good processing quality of the material, partial areas can also be reworked and renovated during running production.

KLB INDUSTRIAL EP Rapid

Rapid-setting and quickly reusable epoxy resin coating in smooth or slightly non-slip

KLB INDUSTRIAL PU RX Rapid

Very rapid-setting polyurethane resin coating, light-stable and slip-resistant

KLB INDUSTRIAL PMMA RX

Rapid-setting, slip-resistant PMMA coating for wet areas

KLB INDUSTRIAL DECOR PMMA

Rapid-setting, slightly slip-resistant PMMA decorative coating for dry areas

"The chemistry has to be right – also between the floor coating and the specification profile. Here it is our task to offer you the perfect solution for every requirement. Chemical substances and their effects on floor coverings are strongly dependent on the concentration of the respective substance as well as the exposure time. KLB Kötztal actively supports you in all questions of chemical resistance. Years of experience with coating materials for chemical production and storage areas make us a reliable partner when it comes to recommending chemical-resistant floorings. No matter whether it's WHG-certified coating systems, special solutions for electroplating plants or floor coverings exposed to fuels, oil, engine oil, water, solvents, alkalis, saline solutions as well as mineral acids and other chemicals.

KLB INDUSTRIAL EP RX Robust

Slip-resistant, durable epoxy resin coating to be scattered with coloured sand

KLB PROTECT WHG EP

Chemical-resistant epoxy resin coating for water protection (WHG) with approval according to DIBt (building authority approval)

KLB PROTECT WHG CONDUCTIVE EP

Chemical-resistant epoxy resin coating for water protection (WHG) with DIBt approval (building authority approval), electrically conductive

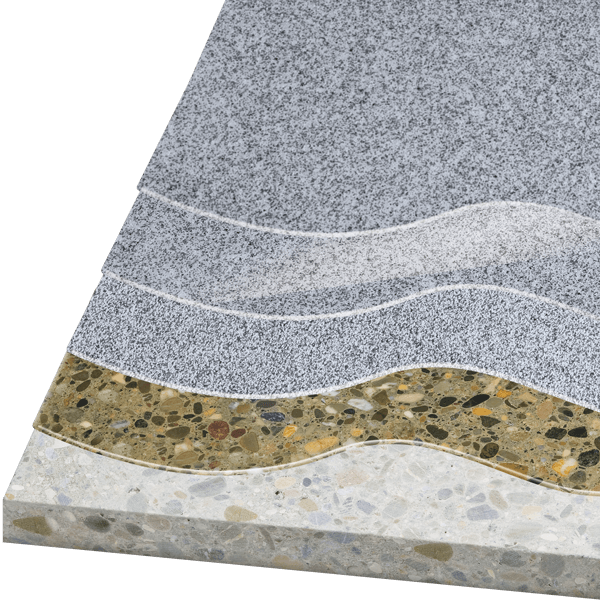

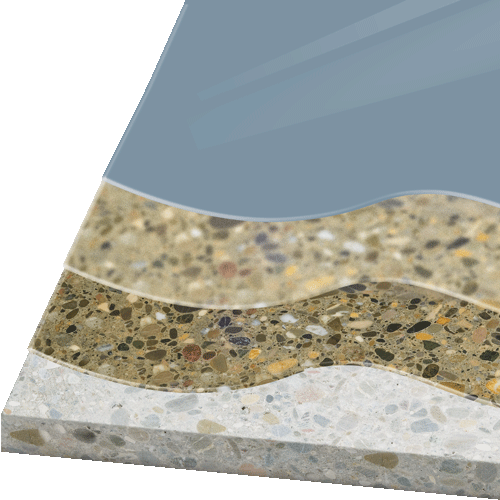

Let out floors inspire you

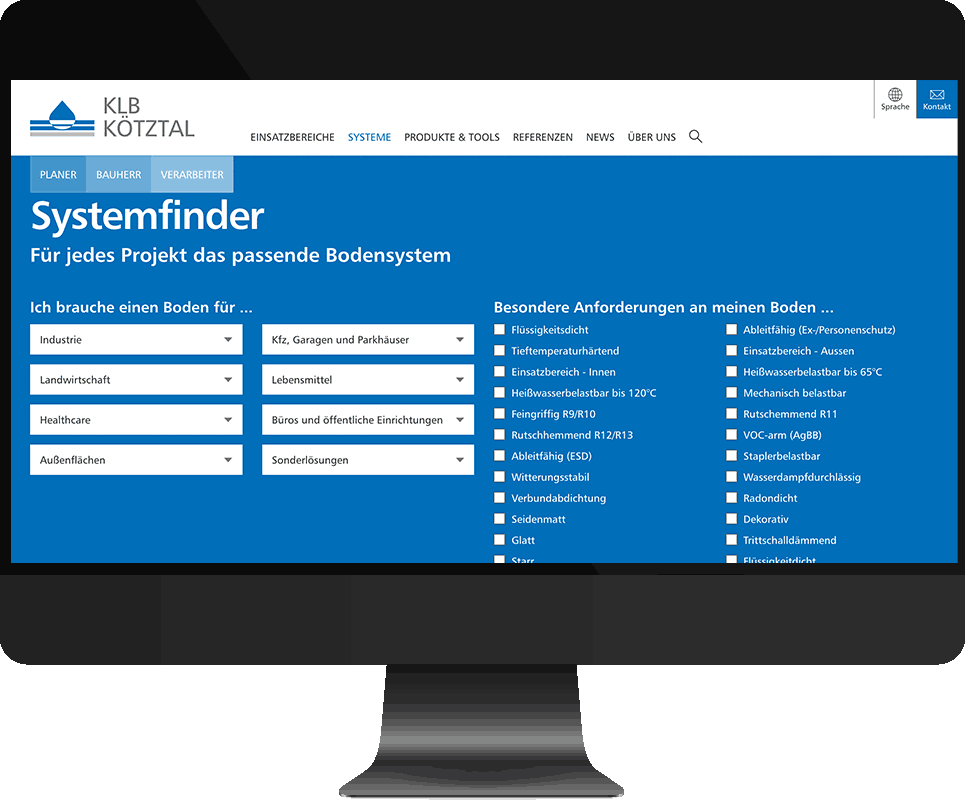

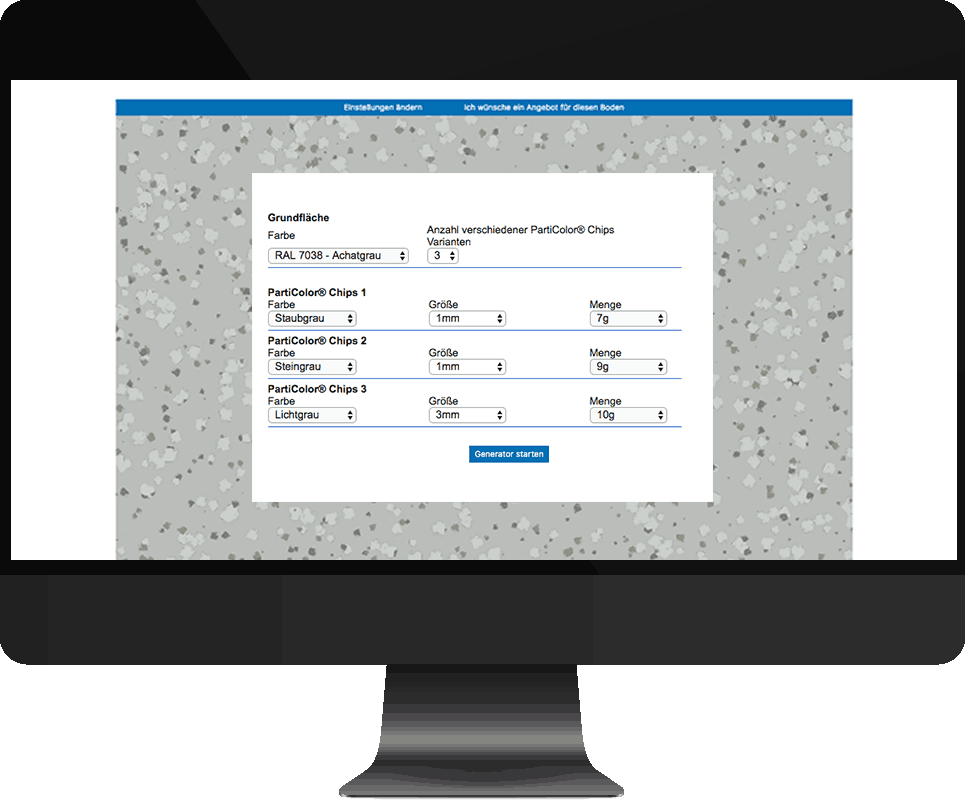

Have a go at designing your ideal floor! Or get to know the differences and strengths of our various floor systems

Configure your individual floor system so it is tailored to your project’s specific demands. If there should be several options available, you can compare the systems in more detail.

Get to the System Finder

KLB floor systems do not only offer a wide variety and choice of functional solutions. Also when it comes to visual appearance, there are hardly any limits set to your creativity and individuality. Just get in and try it out. Have fun!

Get to the Floor Designer

Always at your service with professional advice

If you still have questions about our products or systems – please contact us. We will get in touch with you immediately.

Phone

Our competent KLB team will be happy to provide you with quick and straightforward personal advice on our coating systems.

General enquiries

+49 8223 96 92 0

Order hotline

+49 8223 96 92 222

Hotline for technical enquiries

+49 8223 96 92 333

Sales service

+49 8223 96 92 777

Hotline to our export department

+49 8223 96 92 239

References

The industrial floor coating in the showroom of company Multivac is not only a presentation and sales area for machines, but also a stage for a variety of challenges to the floorin...

An ESD-dissipative floor covering is the guarantee for intact products in both new construction and renovation projects. In addition, employees are protected from electrostatic dis...

In the Augsburg Industrial Park, the original subfloor condition was oil-contaminated, partly cracked and consisted of worn existing coatings or partly new and old concrete. In ord...

Especially in the food industry, a robust covering with high mechanical load-bearing capacity is crucial. In addition to this, the industrial flooring must withstand rapid temperat...

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome