ESD conductivity for protecting electronic components

ESD-conductive flooring in the production hall of company Inpotron.

Assignment and requirements

In the electronic’s production and manufacturing area of Inpotron, the industrial floor coating meets current ESD requirements according to DIN EN 61340-5-1. The top priority is to protect sensitive electronic components from electrostatic discharge.

Particularities and challenges

An ESD-dissipative floor covering is the guarantee for intact products in both new construction and renovation projects. In addition, employees are protected from electrostatic discharge.

The water vapour-permeable system also allows rising damp from the heated concrete slab to be transported upwards. For a good indoor climate, the build-up only contains low-VOC products. The covering is easy to clean taking into consideration our respective cleaning and maintenance recommendation for conductive floors.

The solution

The priming coat EP 782 E Spachtelgrund was applied on top of the very adhesive universal primer EP 724 E Haftgrund Super to level the substrate. This levelling layer creates the basis for a pore-closed surface.

Together with copper tape KLB-Kupferband, EP 799 Ableitgrund forms the cross-conductible base coat. This is followed by a flow coating using EP 785 EL+ and a final matt sealant PU 813 EL+/ESD in the colour approx. RAL 7035, which gives a homogeneous surface appearance.

The Project

Category: Manufacturing hall

Area size: 2,000 m²

Area type: Production facilities for electronic components

Completion: June 2022

Build-up of system

- Matt top sealer KLB-SYSTEM POLYURETHAN PU 813 EL+/ESD

- Top coat KLB-SYSTEM EPOXID EP 785 EL+

- Conductive layer KLB-SYSTEM EPOXID EP 799 Ableitgrund, with copper strip KLB-Kupferband attached underneath

- Scratch coat with KLB-SYSTEM EPOXID EP 782 E Spachtelgrund

- Primer KLB-SYSTEM EPOXID EP 724 E Haftgrund Super

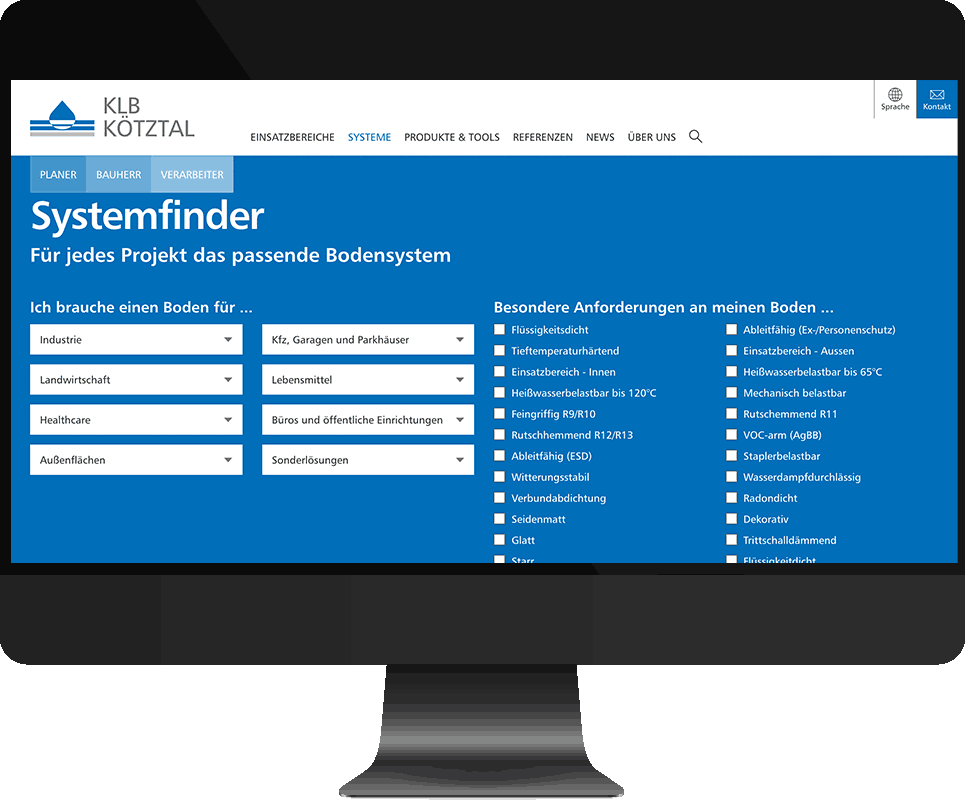

The object shown has a special build-up. The installation technique and product composition for this flooring was developed and implemented by our customer. The tested and proven KLB systems provide a reliable basis for many such out-of-the-ordinary applications. For special circumstances or if you have individual design requirements, you can also optionally supplement or adapt our systems with other products from our high-quality portfolio. KLB consultants will be happy to answer any technical questions you may have. You can find KLB systems recommended by us on our website at: www.klb-koetztal.de/en/systemfinder

Let our floors inspire you

Have a go at designing your ideal floor! Or get to know the differences and strengths of our various floor systems

Configure your individual floor system so it is tailored to your project’s specific demands. If there should be several options available, you can compare the systems in more detail.

Get to the System Finder

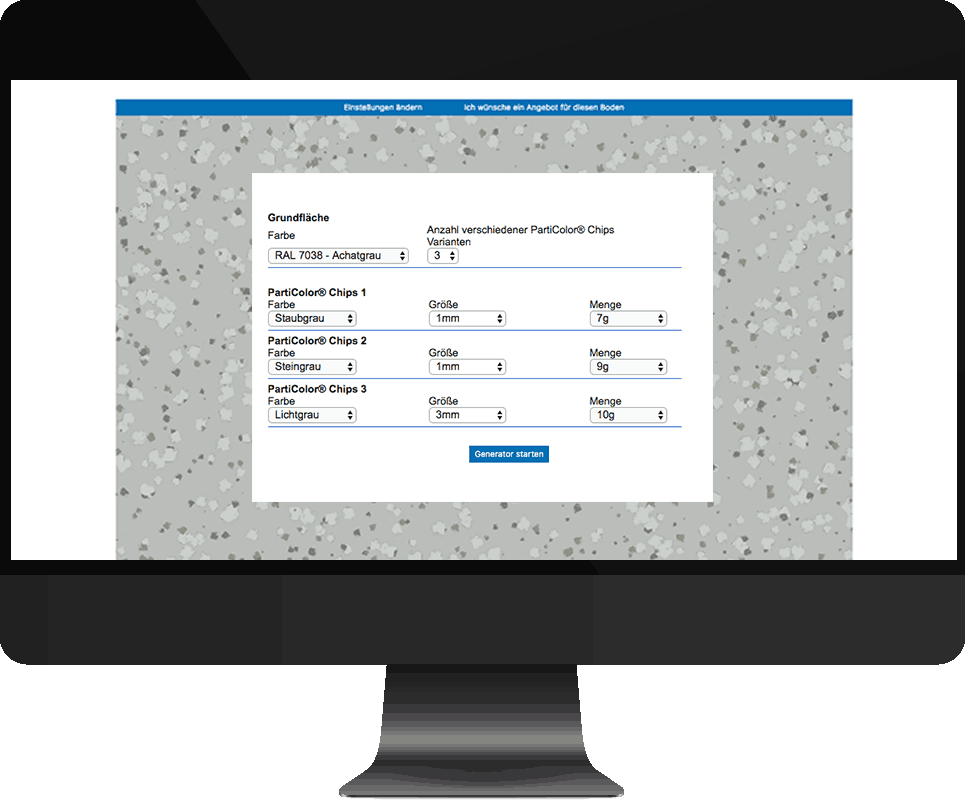

KLB floor systems do not only offer a wide variety and choice of functional solutions. Also when it comes to visual appearance, there are hardly any limits set to your creativity and individuality. Just get in and try it out. Have fun!

Get to the Floor Designer

More references

Due to the constant visitor traffic, only a very hard-wearing surface would be suitable for the floor renovation of the Tegelberg cable car. Pebbles, walking sticks or ski poles an...

The industrial floor coating in the showroom of company Multivac is not only a presentation and sales area for machines, but also a stage for a variety of challenges to the floorin...

In the Augsburg Industrial Park, the original subfloor condition was oil-contaminated, partly cracked and consisted of worn existing coatings or partly new and old concrete. In ord...

Especially in the food industry, a robust covering with high mechanical load-bearing capacity is crucial. In addition to this, the industrial flooring must withstand rapid temperat...

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome