Industrial floor coating for a showroom in Bielefeld

Designed for presentation and production.

Assignment and requirements

For their showroom, the company Schüco, as a manufacturer of window, door and façade systems, needed a suitable floor covering that could withstand mechanical loads when presenting their production facilities and machinery in action. In addition, the floor had to be in a special colour tone of approx. RAL 6000 patina green to harmonise with the corporate design.

Particularities and challenges

The decorative floor coating should have a low VOC content and good colour stability due to the high incidence of light from outside.

With a light anti-slip setting, the floor provides a certain grip, e.g. for when it is soiled during production activities. For machine operators, this slight slip-resistance ensures work safety, and surefootedness for visitors to the exhibition space.

The solution

For the floor coating to retain a permanently attractive appearance, it should be undemanding in terms of cleaning and maintenance. The matt sealer KLB-SYSTEM POLYURETHAN PU 806 E – R10 gives the coating a visually appealing finish. Set to slip resistance level R10, the floor reduces the risk of slipping and thus occupational accidents during manufacturing. Due to its impact resistance and good mechanical load-bearing capacity, the floor is extremely durable and economical.

As all products used are certified with the Eurofins label “Indoor Air Comfort Gold”, the entire system build-up meets the emission limits according to AgBB or ABG and also those of other European countries.

The Project

Category: Exhibition space and production area for sliding doors

Area size: 3,600 m²

Area type: Presentation of machines in real production environment

Completion: November 2021

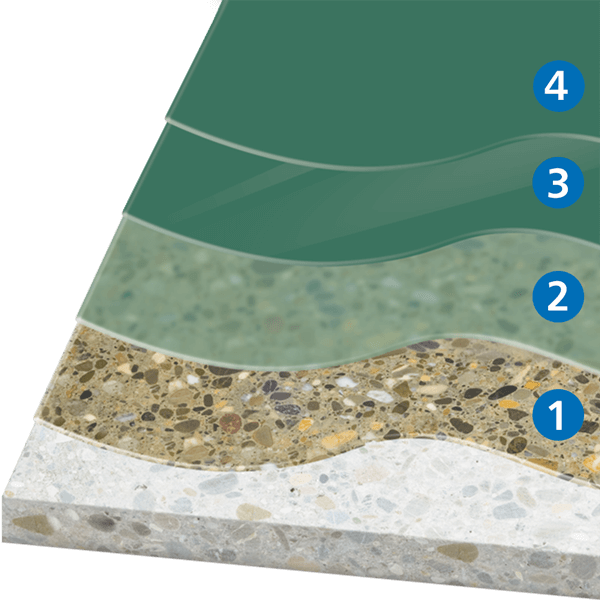

Build-up of system

- Matt sealer KLB-SYSTEM POLYURETHAN PU 806 E – R10

- Top coat KLB-SYSTEM POLYURETHAN PU 420

- Scratch coat with KLB-SYSTEM POLYURETHAN PU 420

- Primer KLB-SYSTEM EPOXID EP 57

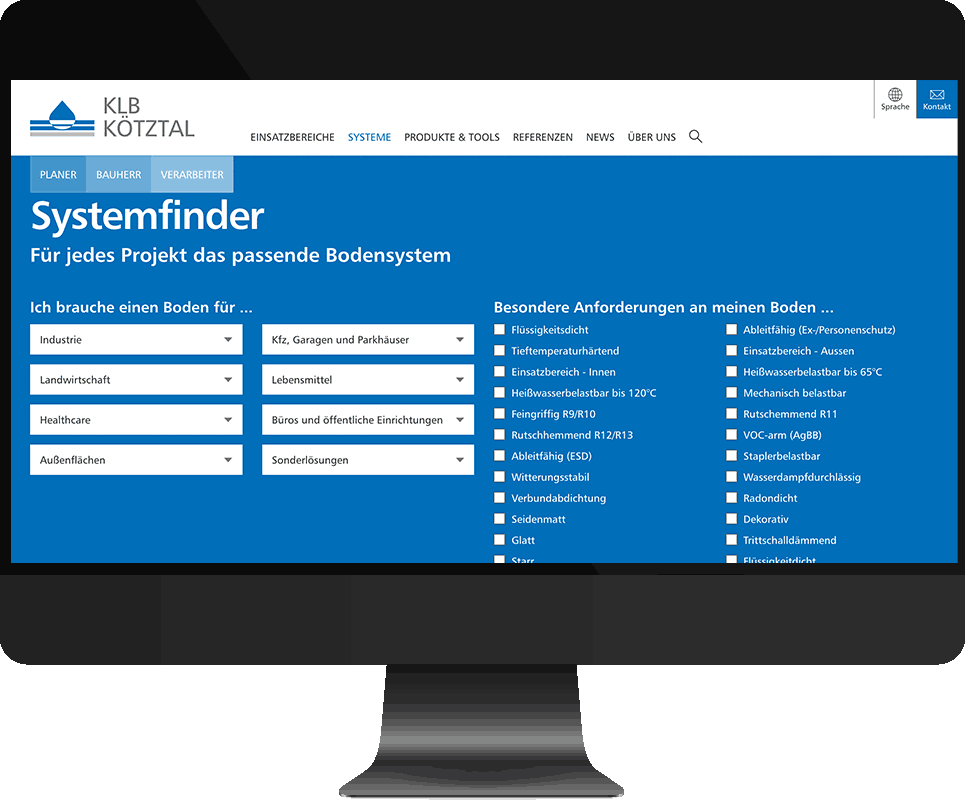

The object shown has a special build-up. The installation technique and product composition for this flooring was developed and implemented by our customer. The tested and proven KLB systems provide a reliable basis for many such out-of-the-ordinary applications. For special circumstances or if you have individual design requirements, you can also optionally supplement or adapt our systems with other products from our high-quality portfolio. KLB consultants will be happy to answer any technical questions you may have. You can find KLB systems recommended by us on our website at: www.klb-koetztal.de/en/systemfinder

Let our floors inspire you

Have a go at designing your ideal floor! Or get to know the differences and strengths of our various floor systems

Configure your individual floor system so it is tailored to your project’s specific demands. If there should be several options available, you can compare the systems in more detail.

Get to the System Finder

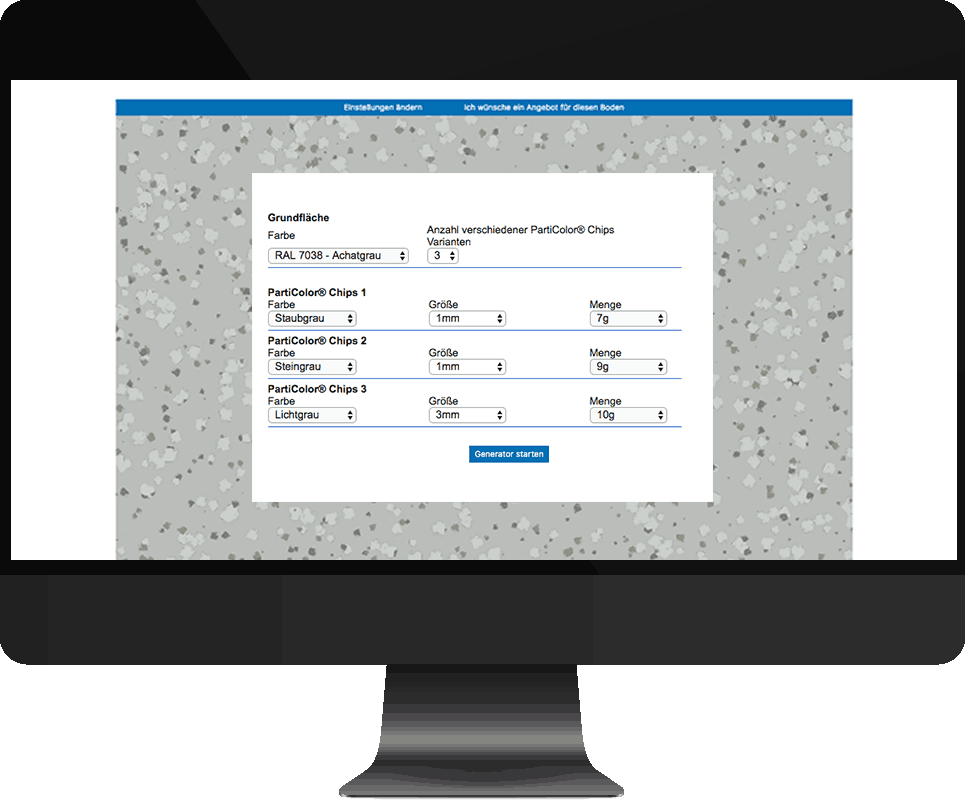

KLB floor systems do not only offer a wide variety and choice of functional solutions. Also when it comes to visual appearance, there are hardly any limits set to your creativity and individuality. Just get in and try it out. Have fun!

Get to the Floor Designer

More references

The industrial floor coating in the showroom of company Multivac is not only a presentation and sales area for machines, but also a stage for a variety of challenges to the floorin...

An ESD-dissipative floor covering is the guarantee for intact products in both new construction and renovation projects. In addition, employees are protected from electrostatic dis...

In the Augsburg Industrial Park, the original subfloor condition was oil-contaminated, partly cracked and consisted of worn existing coatings or partly new and old concrete. In ord...

Especially in the food industry, a robust covering with high mechanical load-bearing capacity is crucial. In addition to this, the industrial flooring must withstand rapid temperat...

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome