Industrial kitchen with high exposure to moisture and hot water

Hot water-resistant, rapid-setting and flexibilised acrylic resin coating in kitchen areas.

Assignment and requirements

Floors in kitchen areas must be robust and able to withstand hot water. In wet areas, a non-slip surface is also necessary to ensure occupational safety. Downtime of the kitchen operations should be kept as low as possible when carrying out the flooring work.

Particularities and challenges

Short-term exposure to high water temperatures of up to approx. 80 °C (176 °F) and good resistance to common chemicals were the main requirements for this project. The solution was a flexible floor coating with a waterproof membrane layer, that can be scattered to achieve a certain slip-resistance. For the optical differentiation between “clean” and “unclean” areas, this was done with KLB coloured sand CQS in different mixtures.

The solution

System M1 KLB INDUSTRIAL PMMA RX cures to a tough and hard synthetic resin. With a very fast curing and direct recoatability, the coating offers high resistance to mechanical stress and also to the chemicals in cleaning agents that are used in commercial kitchens. By scattering the surface with different sand mixtures of KLB coloured sand CQS, it was possible to visually distinguish the kitchen areas from each other. In addition, the surface was given an anti-slip effect, which ensures a high level of work safety and virtually eliminates slipping, even on wet floors. Finishing with a top sealer is particularly suitable for wet-stressed and slip-resistant scattered coatings in the interior.

The flexible, waterproof membrane layer protects the substrate from water or any other substances that could damage concrete or underlying structural components. Specially matched PMMA resins also make it possible to connect walls, penetrations and landings to the floor surface without any joints. This facilitates cleaning and leads to increased hygiene in the various kitchen areas.

The Project

Category: Social facilities

Area size: 550 m²

Area type: Industrial kitchen

Completion: April 2017

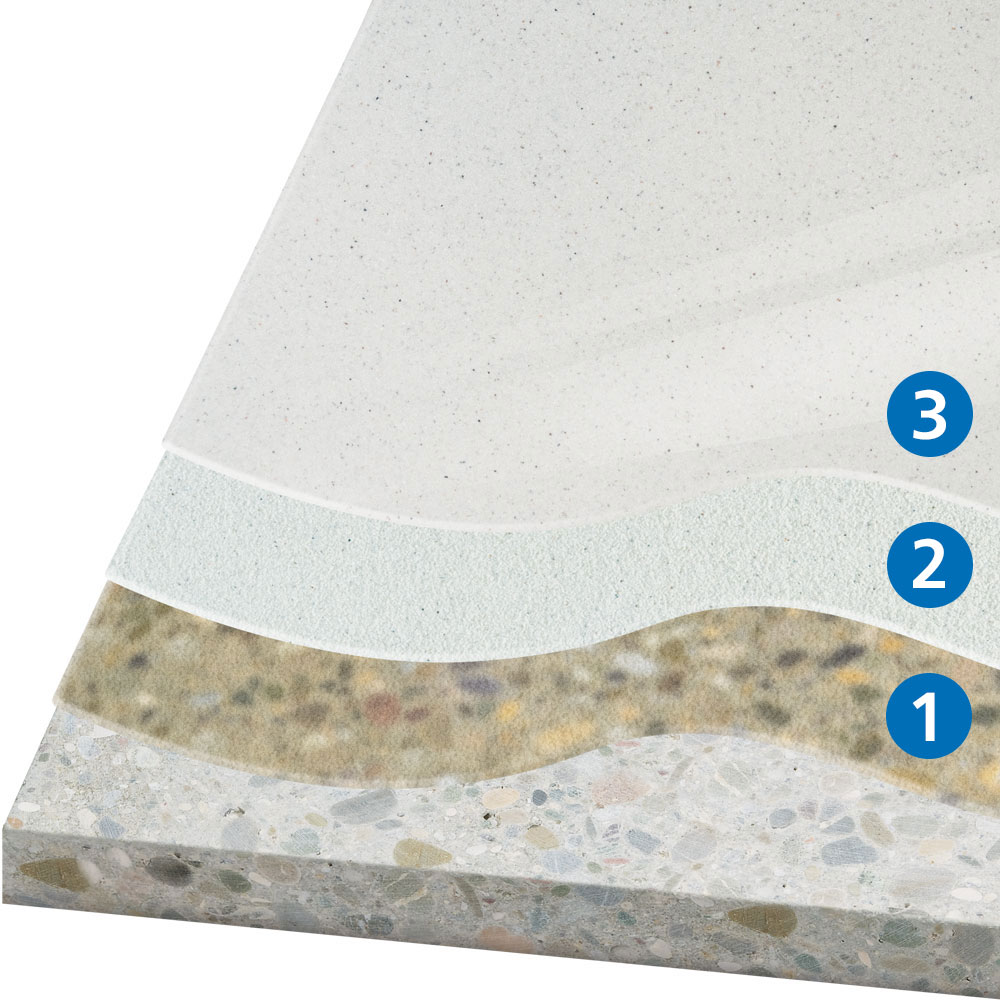

Build-up of system

- Top sealer KLB-SYSTEM ACRYL AC 826

- Base layer with KLB-SYSTEM ACRYL AC 313 and mixed sand KLB-Mischsand 2/1, fully scattered with coloured quartz sand KLB-Colorquarzsand 0.7/1.2 mm

- Primer KLB-SYSTEM ACRYL AC 20, openly scattered with quartz sand KLB-Quarzsand 0.7/1.2 mm

Let our floors inspire you

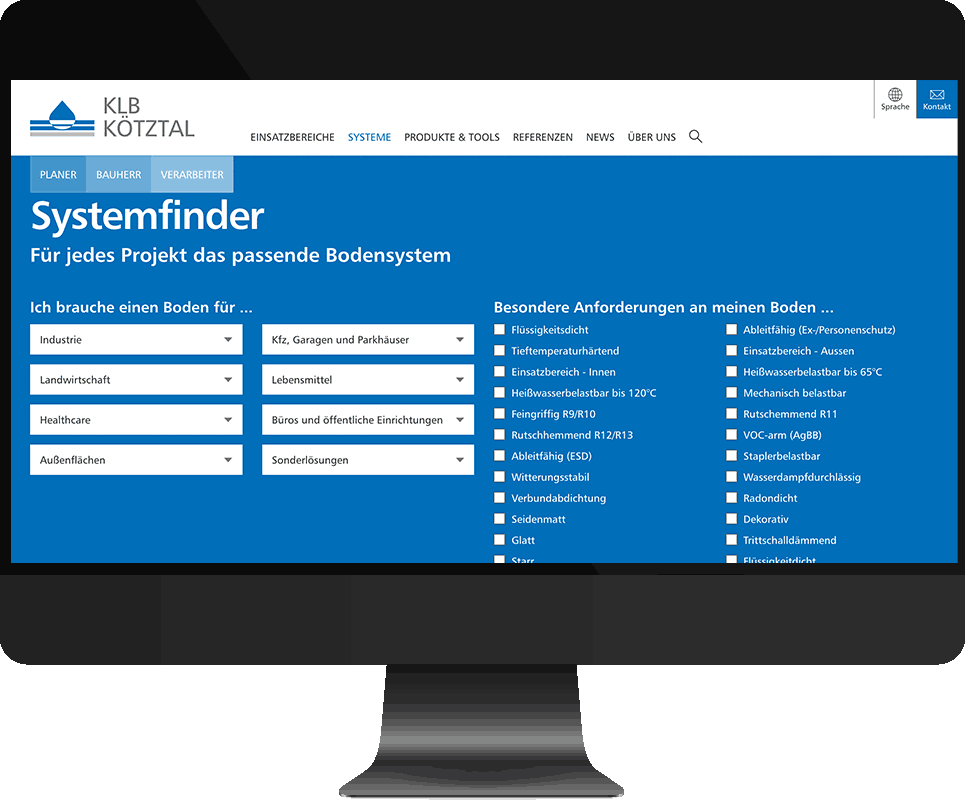

Have a go at designing your ideal floor! Or get to know the differences and strengths of our various floor systems

Configure your individual floor system so it is tailored to your project’s specific demands. If there should be several options available, you can compare the systems in more detail.

Get to the System Finder

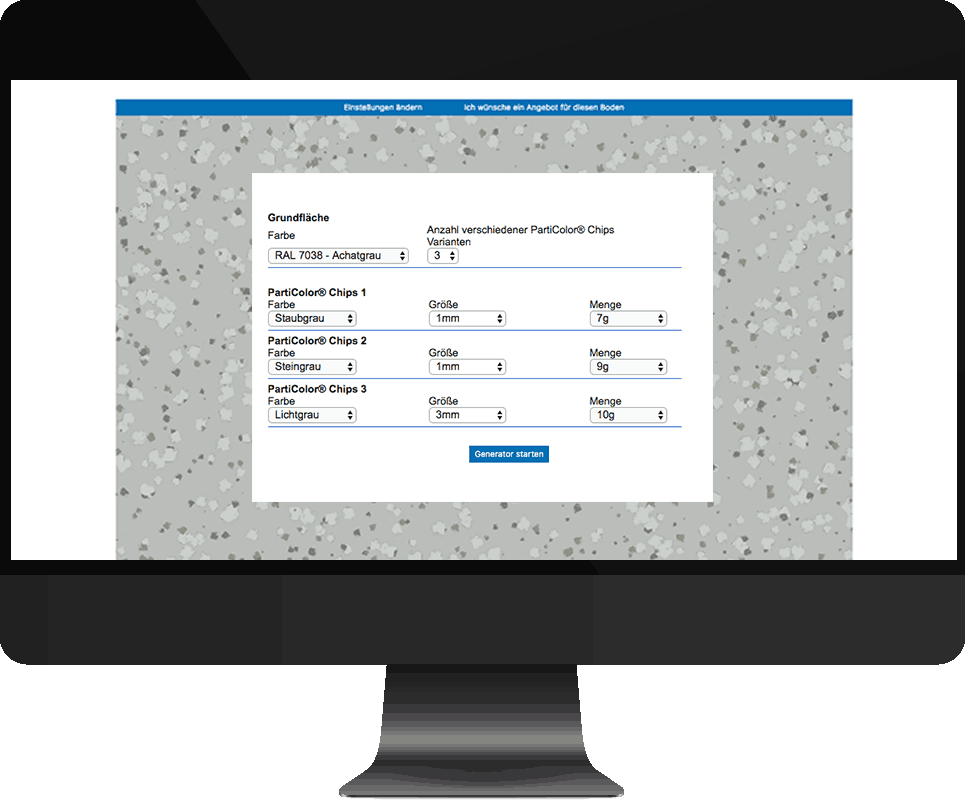

KLB floor systems do not only offer a wide variety and choice of functional solutions. Also when it comes to visual appearance, there are hardly any limits set to your creativity and individuality. Just get in and try it out. Have fun!

Get to the Floor Designer

More references

The bakehouse of a pastry shop or bakery is subject to intensive daily use: besides regular cleaning, the floor comes into contact with a wide range of liquids and other food ingre...

An ESD-dissipative floor covering is the guarantee for intact products in both new construction and renovation projects. In addition, employees are protected from electrostatic dis...

Especially in the food industry, a robust covering with high mechanical load-bearing capacity is crucial. In addition to this, the industrial flooring must withstand rapid temperat...

The wall coating in this reference had to be resistant to water and chemical substances, which was also important in view of the frequent cleaning of the facilities to make floor m...

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome