System I2

KLB CHEMORESIN PU-BETON RX

Industrial flooring for wet areas exposed to hot water and chemicals, with slip-resistant surface

Build-up of system

- Top sealer CHEMORESIN PU-BETON 4080

- Mortar coating with CHEMORESIN PU-BETON 4004/4006/4009, scattered with KLB quartz sand or corundum depending on the desired slip-resistance (please refer to test certificates)

- Primer CHEMORESIN PU-BETON 4051

Downloads

System information

Cleaning recommendation

Build-up of system – single products used

Each of our coating systems is a combination of perfectly matched products.

3-component PU-BETON primer as base layer and system component for CHEMORESIN PU-BETON coverings. Optimises adhesion and reduces bubble formation. Can be accelerated with ...

High-quality, trowelable 3-component PU-BETON levelling mortar for priming and levelling rough, milled or blasted substrates prior to the application of CHEMORESIN PU-BETON. A...

High-quality, trowelable 3-component PU-BETON coating in a layer thickness of 6 mm. Can be adjusted to different slip resistance grades from R9 to R13. To be used preferably i...

High-quality, trowelable 3-component PU-BETON coating in a layer thickness of 9 mm. Can be adjusted to different slip resistance grades from R9 to R13. To be used prefera...

Always at your service with professional advice

If you still have questions about our products or systems – please contact us. We will get in touch with you immediately.

Phone

Our competent KLB team will be happy to provide you with quick and straightforward personal advice on our coating systems.

General enquiries

+49 8223 96 92 0

Order hotline

+49 8223 96 92 222

Hotline for technical enquiries

+49 8223 96 92 333

Sales service

+49 8223 96 92 777

Hotline to our export department

+49 8223 96 92 239

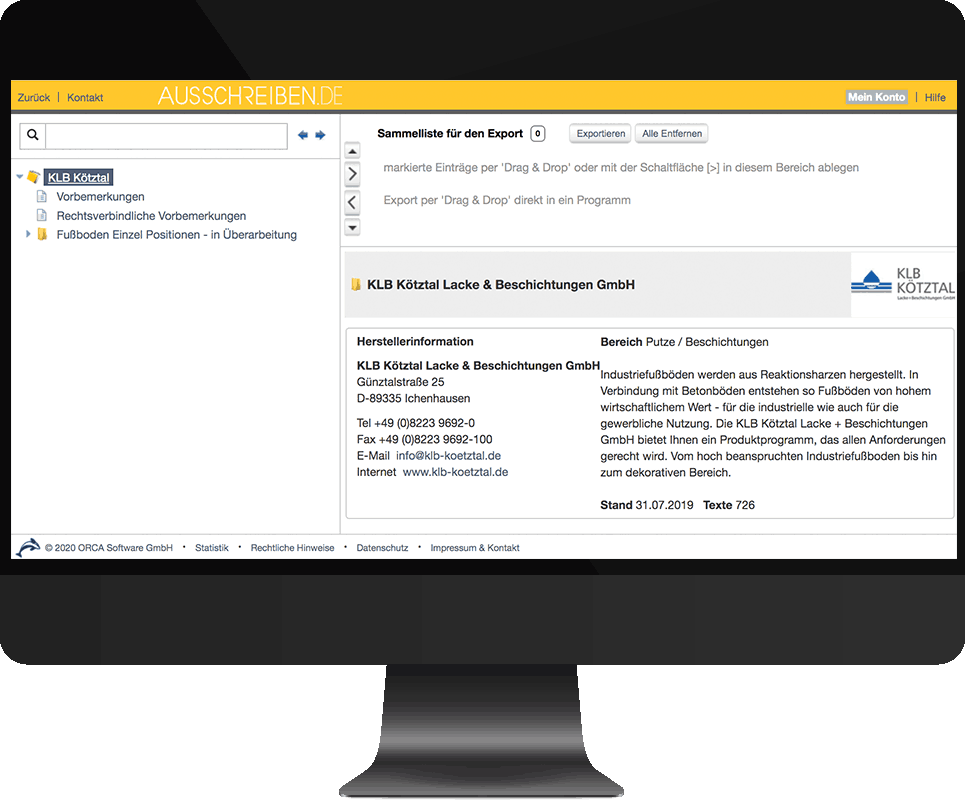

Making work a little easier: Ausschreiben.de provides you with a large number of prepared tender documents for every project type and requirement.

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome