System H2

KLB KITCHEN LOW-VOC PU

Low-emission, slip-resistant polyurethane coating for kitchens

Build-up of system

- Top sealer KLB-SYSTEM POLYURETHAN PU 484

- Base coat with KLB-SYSTEM POLYURETHAN PU 424, filled with mixed sand KLB-Mischsand 3/1, then fully scattered with KLB coloured quartz CQS

- Second waterproofing layer KLB-SYSTEM ABDICHTUNG CW 510

- First waterproofing layer KLB-SYSTEM ABDICHTUNG CW 510

- Scratch coat with KLB-SYSTEM EPOXID EP 53 Spezialgrund AgBB and mixed sand KLB-Mischsand 2/1, openly scattered with KLB quartz sand

- Primer KLB-SYSTEM EPOXID EP 53 Spezialgrund AgBB

Downloads

System information

Cleaning recommendation

Build-up of system – single products used

Each of our coating systems is a combination of perfectly matched products.

Low-emission, AgBB-tested 2-component epoxy resin with high moisture tolerance and particularly good wettability properties. Suitable for damp and problem substrates, aft...

Standard filling sand mixture for scratch coats and as an additive to unfilled coating systems based on epoxy or acrylic resins, such as for EP 99, AC 313, AC 320, AC 390.

High-quality, transparent and light-resistant 2-component polyurethane resin for use as a top sealer on slip-resistant coloured sand scattered coatings and as a clear resin layer o...

KLB-SYSTEM ABDICHTUNG CW 510 is an elastic, crack-bridging, low-emission 2-component polyurethane composite waterproofing, which is used for sealing floors in wet areas b...

Always at your service with professional advice

If you still have questions about our products or systems – please contact us. We will get in touch with you immediately.

Phone

Our competent KLB team will be happy to provide you with quick and straightforward personal advice on our coating systems.

General enquiries

+49 8223 96 92 0

Order hotline

+49 8223 96 92 222

Hotline for technical enquiries

+49 8223 96 92 333

Sales service

+49 8223 96 92 777

Hotline to our export department

+49 8223 96 92 239

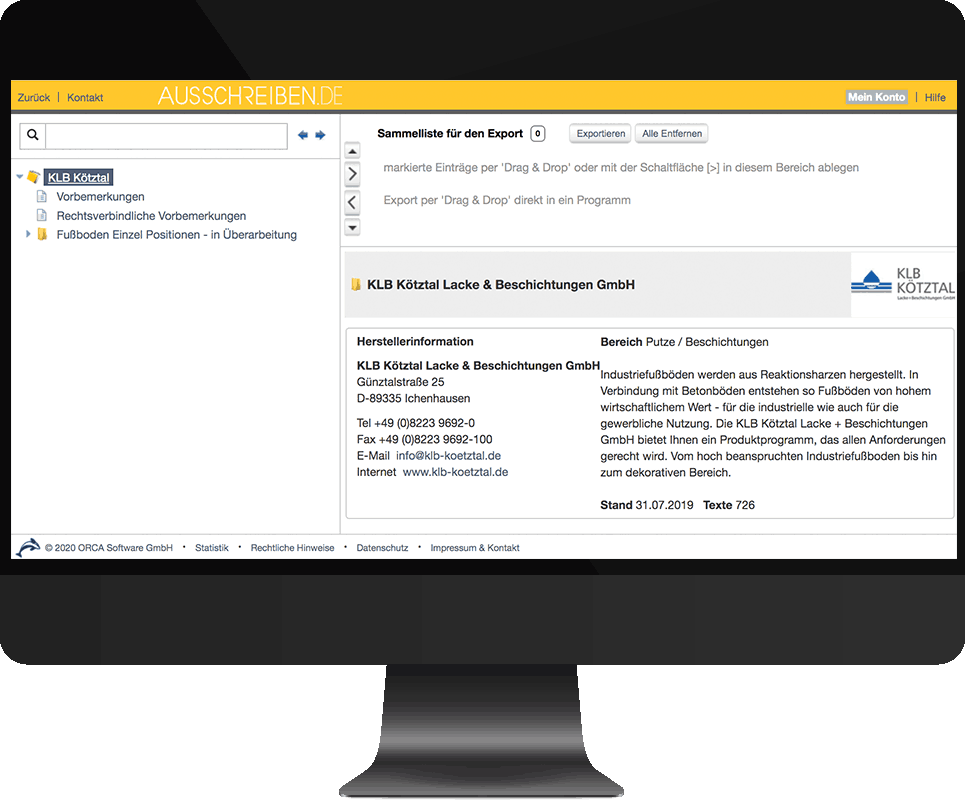

Making work a little easier: Ausschreiben.de provides you with a large number of prepared tender documents for every project type and requirement.

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome