Load-bearing CHEMORESIN flooring for a large bakery

Thermically and mechanically highly resistant PU-Concrete coating for food processing areas.

Assignment and requirements

Fresh baked goods are produced daily at industrial bakery “Der Beck GmbH” – a considerable challenge for the floor: it must withstand thermal stress from oven racks heated to 200 °C / 392 °F, remain seamless and hygienic, and endure mechanical loads over extended periods.

Particularities and challenges

The floor needed to resist both sudden temperature fluctuations and daily rolling loads without showing any signs of wear.

At the same time, it had to be easy to clean and fully compliant with the hygiene regulations of the food industry. For optimal bond strength, anchoring grooves were milled into the substrate, particularly at edges and transitions areas.

The solution

The robust CHEMORESIN PU-BETON 4006 / 4009 system with R11 V4 slip resistance was installed. In high-load zones, PU-BETON 4009 was applied in a 9 mm layer thickness – specifically developed to withstand extreme mechanical and thermal stress up to 150 °C / 302 °F (dry heat).

The result: a jointless, easy-to-clean, chemically resistant flooring solution that remains dimensionally stable under continuous load – ideal for hygienic and safe use in bakery production environments.

The Project

Category: Production of a large bakery

Area size: 4,500 m²

Area type: Traffic areas in production facilities

Completion: August 2024

Build-up of system

4. Top sealer CHEMORESIN PU-BETON 4080, addition of catalyst CHEMORESIN PU-BETON 4094 KAT

3. Mortar coating with CHEMORESIN PU-BETON 4006/4009, scattering with quartz sand KLB-Quarzsand 0.3/0.8 mm

2. Intermediate and levelling layer CHEMORESIN PU-BETON 4045 (*partial areas)

1. Primer CHEMORESIN PU-BETON 4051

The object shown has a special build-up. The installation technique and product composition for this flooring was developed and implemented by our customer. The tested and proven KLB systems provide a reliable basis for many such out-of-the-ordinary applications. For special circumstances or if you have individual design requirements, you can also optionally supplement or adapt our systems with other products from our high-quality portfolio. KLB consultants will be happy to answer any technical questions you may have. You can find KLB systems recommended by us on our website at: www.klb-koetztal.de/en/systemfinder

Let our floors inspire you

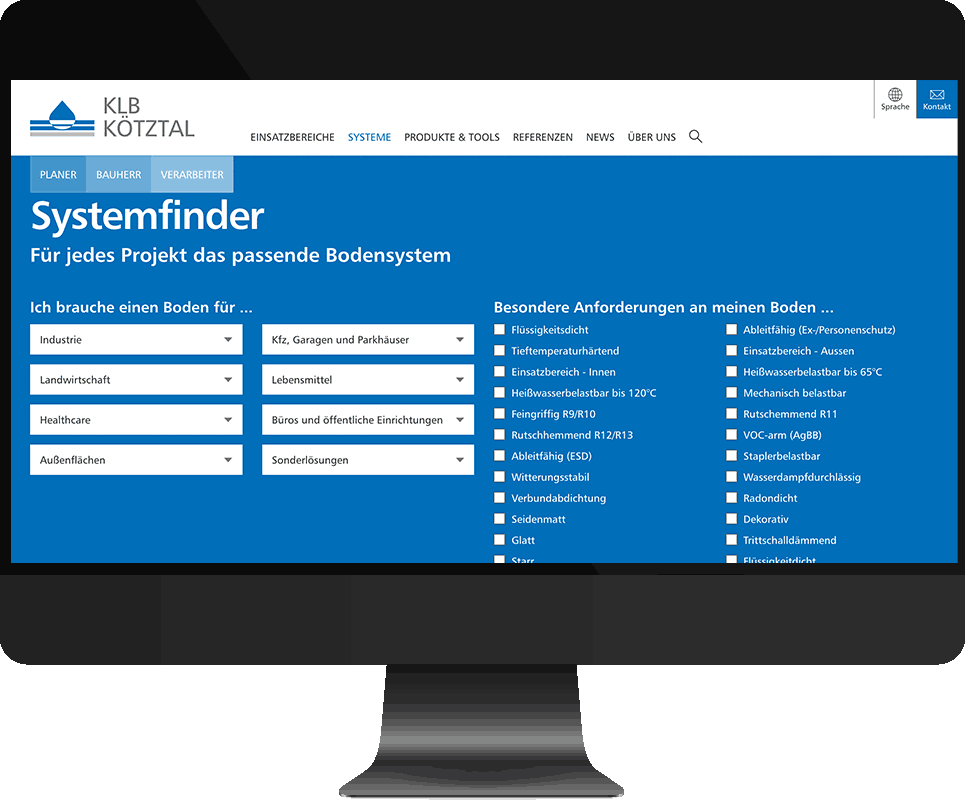

Have a go at designing your ideal floor! Or get to know the differences and strengths of our various floor systems

Configure your individual floor system so it is tailored to your project’s specific demands. If there should be several options available, you can compare the systems in more detail.

Get to the System Finder

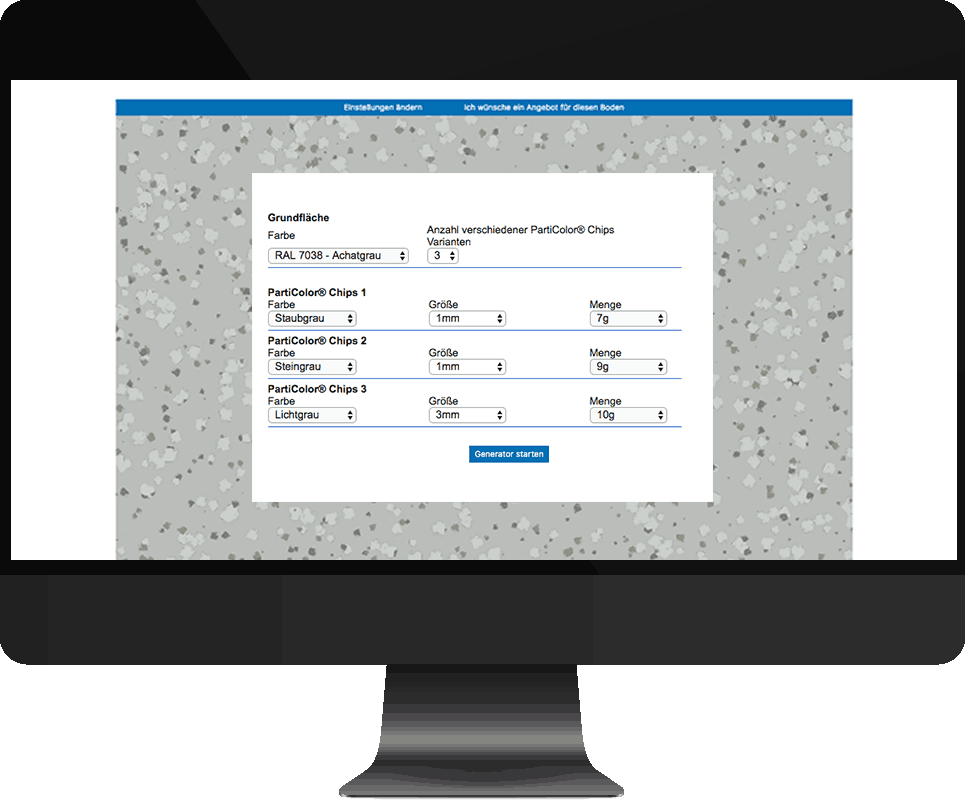

KLB floor systems do not only offer a wide variety and choice of functional solutions. Also when it comes to visual appearance, there are hardly any limits set to your creativity and individuality. Just get in and try it out. Have fun!

Get to the Floor Designer

More references

The heavily stressed concrete showed numerous cracks and spalling, posing a significant dust and safety risk. In some areas, the substrate was so weak that it had to be removed and...

The truck unloading area is exposed to constant stress: heavy goods traffic, moisture, road dirt and de-icing salt in winter. Added to this are chemical impacts from lactic acid.

In the commercial kitchen of VfB Stuttgart soccer club, a hygienic, durable and functional commercial kitchen floor covering was installed. The jointless surface needed to be easy ...

The certified PU kitchen flooring system H2 was successfully installed in a canteen in Gießen, GERMANY. The waterproofing holds EAD 030352‑00‑0503 and is certified based on AbP in ...

Mozilla Firefox

Mozilla Firefox Microsoft Edge

Microsoft Edge Google Chrome

Google Chrome